Learn the tricks of the trade for creating a 2 aircon 1 compressor system that will achieve maximum efficiency. For optimal performance, you should educate yourself on how to select the appropriate components and determine the appropriate ductwork size.

Overview of 2 Aircon 1 Compressor System Design

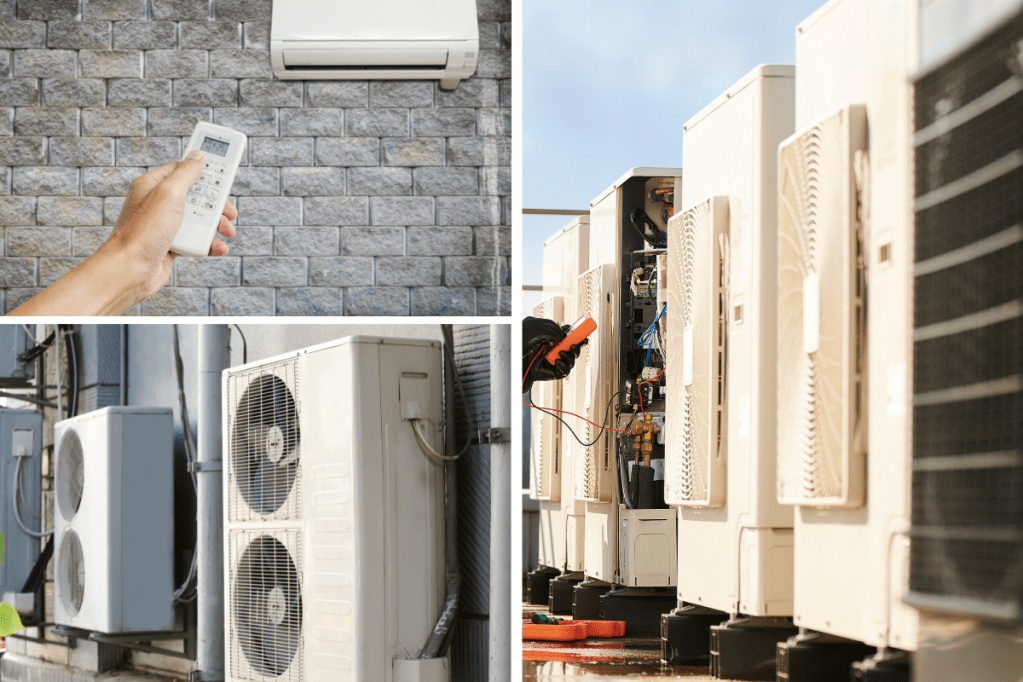

In hot, humid climes, most homes and businesses have air conditioning. Office buildings, shopping malls, and hotels employ the 2 aircon 1 compressor system to regulate indoor air temperature. Its energy-efficient cooling system reduces operational costs.

Selecting air conditioning units and compressors to fulfill space cooling needs is part of designing a 2 aircon 1 compressor system. Calculating the space’s cooling load determines the system’s cooling capacity. After determining the cooling demand, air conditioning systems are chosen based on cooling capability and energy efficiency. The compressors match the air conditioning systems’ total cooling capability.

The next stage in designing a 2 aircon 1 compressor system is sizing the ducting and plumbing for best performance. Pipes carry refrigerant between air conditioning units and the compressor, while ductwork distributes cool air. For efficient cooling, ducting and plumbing must be properly sized. Balance and commissioning the system ensures proper operation.

In conclusion, designing a 2 aircon 1 compressor system requires careful cooling load assessment, selection of air conditioning units and compressors, sizing of ductwork and piping, system balance, and commissioning. Optimizing efficiency and performance involves air conditioning engineering and energy efficiency knowledge. A well-designed and maintained 2 aircon 1 compressor system can save energy and improve building occupant comfort.

Determining the Appropriate Aircon Unit Capacity

Designing a 2 aircon 1 compressor system or any air conditioning system requires determining the aircon unit capacity. Room size, insulation, and occupancy affect the cooling demand, which determines the air conditioner’s capability. To maximize performance and efficiency, use a large air conditioner.

Then, calculate the space’s cooling load to determine aircon unit capacity. This includes room size, number of people, type and number of windows, and insulation. After calculating the cooling load, choose an air conditioner that matches it. Choosing a too-small or too-large air conditioning equipment will result in inadequate cooling and increased operating costs.

The air conditioning unit type also affects capacity. Window, split, and central air conditioners have varied cooling capacity and energy efficiency ratings. To reduce operating costs, choose a space-appropriate air conditioner that satisfies energy efficiency criteria.

In conclusion, air conditioning system design requires selecting the right aircon unit capacity. It needs careful assessment of the cooling load, consideration of room size, insulation, and occupancy, and selection of an air conditioning unit with the right capacity and energy efficiency rating. Appropriate air conditioning design and maintenance can save energy and improve building comfort.

Choosing the Right Compressor for the System

A 2 aircon 1 compressor system’s performance and energy efficiency depend on the compressor. To cool the air conditioning units, the compressor compresses refrigerant gas. The right compressor depends on space cooling load, air conditioning unit type, and energy efficiency rating.

Cooling load is the first consideration when choosing a compressor for a 2 aircon 1 compressor system. The sum of the air conditioning units’ cooling capacities is the system’s cooling load. To provide sufficient cooling, the compressor must match the air conditioning units’ cooling capacity.

The compressor’s type should also be considered. Window units, split systems, and central systems require different refrigerants and operating pressures. To operate efficiently and reliably, the compressor must be compatible with the air conditioning units’ refrigerant and pressures.

For a 2 aircon 1 compressor system, energy efficiency is another factor to consider. High-efficiency compressors reduce energy use and costs. High-efficiency compressors are usually more expensive. Selecting the right compressor requires balancing initial cost with long-term energy savings.

In conclusion, a 2 aircon 1 compressor system’s compressor must be selected based on the space’s cooling load, the air conditioning units used, and the desired energy efficiency rating. The right compressor ensures air conditioning system performance and energy efficiency. A well-designed and maintained system can save energy and improve building occupant comfort.

Sizing the Ductwork and Piping for Optimal Performance

Air conditioning systems perform best with properly sized ducting and plumbing. Incorrect size reduces airflow, performance, and energy expenditures. So, your aircon system’s duct and pipe sizes must be determined.

When sizing ductwork and pipe, the size of the aircon unit, building architecture and design, number of rooms, and intended use all play a role. HVAC specialists utilize industry standards and formulae to size ducts and pipes based on these parameters. They consider each room’s airflow rate, system static pressure, and air velocity and volume through ducts and pipes.

Undersizing ductwork and piping is prevalent. When ducts or pipes are too tiny to support aircon system airflow, this happens. The system will work harder to circulate air, consuming more energy and shortening its lifespan. Oversizing can disrupt airflow and waste energy.

A trained HVAC expert should size your ductwork and pipes to maximize performance and efficiency. They will calculate the best air conditioning system size using specialist instruments and software. They can also recommend closing leaks and insulating to boost aircon efficiency.

Aircon system design requires suitable ductwork and plumbing sizing. Proper size optimizes performance, energy efficiency, and cost. An skilled HVAC specialist can help you choose the proper ducts and pipes for your air conditioning system and optimize its performance.

Conducting System Balancing and Commissioning

System balancing and commissioning are essential for 2 aircon 1 compressor system performance. System balancing adjusts air and water flow to optimize component performance. This method eliminates hot and cold patches and ensures proper heating and cooling throughout the structure. Commissioning checks that the system was planned and implemented appropriately and satisfies the owner’s standards.

System balancing begins with a system evaluation to determine adjustments. To obtain the desired air and water flow, the balance professional will modify dampers, valves, and fans. The specialist will inspect each building space to guarantee proper heating and cooling. These testing may include detecting temperature and humidity in each room and altering airflow and water flow.

Functional testing, equipment calibration, and system optimization comprise commissioning. The technician will test each system component to make sure it works as designed. They will calibrate and test the electrical and control systems. Ultimately, the technician will optimize the system to fit the owner’s needs and perform optimally.

Finally, system balancing and commissioning are essential for 2 aircon 1 compressor system performance. This technique adjusts air and water flow and verifies system design and installation. The technique eliminates hot and cold patches and ensures adequate heating and cooling throughout the structure. Building owners can save money and improve comfort by balancing and commissioning their HVAC system.