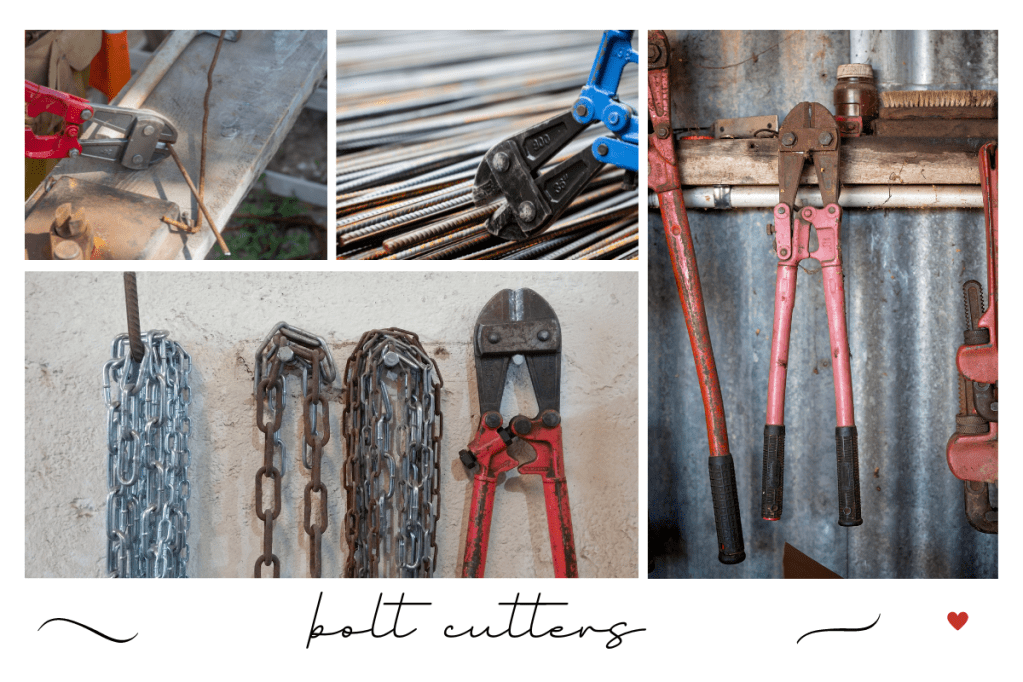

Bolt cutters, a powerful and venerable cutting apparatus, has been extant for well over a century. These formidable tools are fashioned to sunder through thick, obdurate materials such as bolts, chains, and padlocks. While their rudimentary operation may belie their multifarious utility, utilizing them with precision necessitates an intimate comprehension of their composition, competencies, and adept technique. In this comprehensive exposé, we shall elucidate every conceivable facet of bolt cutters, encompassing their genealogy, anatomical constitution, classifications, and safe and efficient usage. Whether one is an enthusiast of DIY, an automotive mechanic, or a seasoned tradesman, mastering the art of cutting with bolt cutters can be a valuable skill that obviates the squandering of time and effort on sundry projects.

Types of Bolt Cutters

Bolt cutters are a formidable tool for sundering obdurate materials such as bolts, chains, and padlocks. These mechanical marvels are crafted in a panoply of types and sizes, each engineered with specific tasks in mind. Comprehending the diverse kinds of bolt cutters available can enhance your proficiency by allowing you to elect the best tool for the job and secure better outcomes. In this article, we shall embark on an odyssey through the multitudinous types of bolt cutters and their applications.

Mini Bolt Cutters

These pint-sized implements are the smallest of the bolt cutters, typically measuring between 8 and 14 inches. They are optimal for shearing slender materials such as wires, cables, and small bolts. Their petite size and svelte design make them facile to transport and utilize in cramped quarters.

Standard Bolt Cutters

Standard bolt cutters range in size from 18 to 42 inches and are ubiquitous in industrial and commercial applications. They are potent enough to slice through bulky materials such as rods, chains, and padlocks with ease. These cutters are available with various jaw sizes, enabling you to select the appropriate size for your specific needs.

Heavy-Duty Bolt Cutters

As the name implies, heavy-duty bolt cutters are designed to hew through the most challenging materials. These colossi measure between 24 and 48 inches and possess a more substantial, sturdier build than standard bolt cutters. They are optimal for slicing through hardened steel rods and bulky chains.

Power-Assisted Bolt Cutters

These are the apogee of bolt cutters, featuring an electric motor that provides supplementary cutting power. They are engineered to shear through the thickest and most resilient materials with minimal exertion. Power-assisted bolt cutters are commonly utilized in automotive and industrial applications where cutting in volume is a requisite.

To conclude, electing the appropriate type of bolt cutters can make a substantial disparity in the efficiency and quality of your work. When selecting the appropriate type of bolt cutters, deliberate the kind of material you will be cutting, the frequency of use, and the scale of the job. With the appropriate tool in your grasp, you can confidently undertake even the most daunting cutting tasks.

How to choose the right Bolt Cutters

Bolt cutters are a multifaceted cutting tool that can expeditiously eviscerate even the most obstinate and corpulent materials. Whether you are a DIY aficionado, mechanic, or a seasoned professional, possessing the fitting bolt cutters can be the difference between inefficacious and accomplished workmanship. Nevertheless, with an array of diverse sizes and types available in bolt cutters, selecting the appropriate one can be a daunting task. In this article, we will elucidate the process of discerning the fitting bolt cutters for your exigencies.

Material Consideration

One of the most pivotal factors to contemplate when selecting bolt cutters is the type of material you will be cutting. Every material has a distinct level of cutting power requisition, and not all bolt cutters are fashioned equal. For instance, if you plan to severe thick steel rods or massive chains, you will necessitate heavy-duty bolt cutters with stouter jaws and handles. Conversely, if you are sectioning through slender wires or cables, smaller, and more lightweight cutters would suffice.

Size Significance

The size of the bolt cutters you choose would depend on the magnitude of the job you are undertaking. Diminutive bolt cutters such as mini bolt cutters are exemplary for sectioning through slender materials in crammed spaces. Nevertheless, if you are cutting through ponderous materials, you will require larger bolt cutters with elongated handles and larger jaws. Standard bolt cutters are typically adequate for most industrial and commercial applications, while heavy-duty bolt cutters are tailored for more heavy-duty tasks.

Jaw Size and Shape

Another indispensable factor to consider when selecting bolt cutters is the jaw size and shape. Different types of bolt cutters are accessorized with diverse jaw sizes and shapes, which can affect their cutting power and versatility. For example, if you are cutting through round materials like chains, you will necessitate bolt cutters with round jaws that can clasp the material securely. On the other hand, if you are slicing through flat materials such as bolts or padlocks, you will require bolt cutters with flat jaws that can slice through the material immaculately and evenly.

Ergonomics and Comfort

Finally, it is pivotal to consider the ergonomics and comfort of the bolt cutters you choose. You will probably be using the cutters for extended periods, so you want to ensure that they are comfortable and facile to use. Look for bolt cutters with ergonomic handles that provide a secure grip and curtail hand exhaustion. You may also wish to consider cutters with non-slip grips or cushioned handles for augmented comfort.

In conclusion, the selection of the appropriate bolt cutters requires meticulous consideration of the material you will be cutting, the magnitude of the job, the jaw size and shape, and the ergonomics and comfort of the cutters. By abiding by these guidelines, you can designate the apt bolt cutters for your requirements and ensure that your cutting tasks are accomplished with efficiency and ease.

Materials of Bolt Cutters

Bolt cutters, the versatile slicing tool that surmounts even the sturdiest of materials, owe their efficaciousness and durability to the diverse materials employed in their assembly. In this discourse, we shall dissect the various components that comprise bolt cutters and the materials that engender their potency.

Handles

Bolt cutters’ handles are usually constructed from either steel or aluminum. Steel handles, with their resilient and tenacious structure, are optimal for more strenuous and laborious undertakings. However, the weight of steel handles can be cumbersome, hindering maneuverability. On the other hand, aluminum handles, with their lightweight and pliant structure, offer unparalleled control and ease of use, especially for lighter applications and precision cutting.

Jaws

The jaws of bolt cutters are shaped from an array of materials, including high carbon steel, chrome-molybdenum steel, and tungsten carbide. High carbon steel jaws are the most prevalent, fit for most circumstances, with strength and durability. Nonetheless, they are not as hardy as other materials and more prone to wear and tear. Chrome-molybdenum steel jaws are sturdier than high carbon steel jaws, capable of withstanding greater force and pressure. Tungsten carbide jaws, the most durable and unyielding, are capable of cutting even the most resilient materials.

Cutting Edges

Bolt cutters’ cutting edges are fashioned from either high carbon steel or hardened steel. High carbon steel cutting edges are suitable for most applications and can be sharpened easily. However, they are less durable than hardened steel and can become blunt rather quickly. Hardened steel cutting edges, more resilient than high carbon steel, can retain their sharpness for longer periods. Nevertheless, they require specialized equipment for sharpening and may prove challenging to maintain.

Additional Components

Other components of bolt cutters, such as screws, pins, and springs, are typically constructed from stainless steel, a material that resists rust and corrosion. Stainless steel is ideal for components that may be exposed to moisture or other environmental factors.

In conclusion, the materials used in the construction of bolt cutters play a pivotal role in determining their efficacy, durability, and reliability. It is crucial to consider the materials used for the handles, jaws, cutting edges, and additional components when selecting bolt cutters. By choosing the appropriate materials, you can ensure that your bolt cutters will perform optimally, providing you with reliable cutting performance for an extended period.

Advantages of Bolt Cutters

Bolt cutters are an incredibly multifaceted and robust cutting tool with a long-standing history. Their applications have spanned several fields, including the construction industry, automobile maintenance, and even in law enforcement. In this article, we will expound on the advantages of employing bolt cutters.

Versatility

One of the primary virtues of bolt cutters is their multifariousness. These cutters can be utilized to excise a broad range of materials, including steel rods, chains, wires, cables, bolts, padlocks, and more. Consequently, they prove to be indispensable to individuals or companies that deal with materials of substantial heft.

Potent Cutting Capability

The bolt cutters are designed to convey prodigious cutting strength, making them incredibly efficacious in dissecting resistant materials. They are contrived to transfer the maximum force to the cutting edges, culminating in neat and precise cuts. With the proper bolt cutters, you can excise thick steel rods and chains in a matter of seconds.

Efficiency and Time-saving

The efficiency of bolt cutters is another hallmark of their virtuosity. They can slice through materials rapidly and capably, making them the quintessential tools for time-sensitive tasks. With bolt cutters, you can excise materials effortlessly, trimming the time and energy necessary to complete the task.

Durability and Longevity

Built to withstand rigorous usage, bolt cutters tout remarkable sturdiness, which is another asset they bring to the table. They are fashioned using high-quality materials, such as steel and aluminum, that can endure the demands of heavy utilization. With appropriate care and upkeep, bolt cutters can serve for a protracted period, making them a lucrative investment.

Ease of Use

Bolt cutters are relatively facile to operate, requiring no specialized skills to wield. They come in assorted sizes and shapes, allowing users to select the precise tool for their specific needs. Bolt cutters with ergonomic handles can provide a secure grip, curbing hand fatigue and enhancing comfort during usage.

In conclusion, bolt cutters tout several benefits, including versatility, potent cutting capability, efficiency, durability, and ease of use. They are the ultimate tools for individuals and businesses that require a robust and dependable cutting tool. When selecting bolt cutters, it is crucial to consider the intended purpose, materials, and features to guarantee that you choose the apt tool for your exigencies.